About...

An Engineer’s backstory – Are Engineers born, or made?

A brief and lighthearted history of an Engineer trapped in an Engineers body.

In The Beginning...

In the beginning, from a very young age I always wanted to know how things worked and took them apart in no time. “…A very destructive child…” my Dad used to say!

The first word I ever uttered was ‘tractor’ as it was one of my first toy’s and it completely transfixed me. A year or so later, and another favourite toy – my pedal car… (The pathway to a lifeltime ambition starts here – read on.)

One Christmas as an 8 year old, I asked my parents for an old lawnmower, some planks of wood, and some pram wheels. It was too mcuh for an accountant and a history teacher to comprehend – ‘Why on earth does he want such things…??’

“Of course you want to make your own motorised gokart – there, there” they said a little disparagingly.

Santa bought no go-kart parts that year – of course – nor any years thereafter, and between you and me I think they were very dissappointed I wasn’t going to become the musician – poet – linguist they hoped hoped for…

To this day that lifetime ambition to do my own vehicle still exists, and I plan to design and build my own track day car – based loosly on a Le Mans style Group C car – but it will have to wait until retirement. And so my love of cars – particulalry the beautiful sports cars of the 1960’s – along with a general interest in technical things and Engineering, was born.

Given my backstory, I strongly believe true Engineers are born, not made. Call it a vocation I suppose…

In my school days, nobody had mentioned engineering as a job, because I don’t think my parents (an Accountant and a History teacher) knew what it was at the time. But at the age of 15 I’d discovered what it was for myself, and that I could even do it for a living. The stuff of dreams eh!

My teenage years were spent doing up bicycles and selling them, and keeping my worn out motorbike going. The best bike I’d ever owned at the time was a nearly new Kawasaki KH 250. Fab!

And Then...

Then, in my student year’s while studying engineering, my grant cheques were used for restoring an old 1971 Triumph Vitesse…

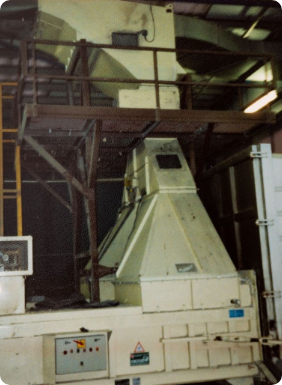

Having graduated and started work in 1988 for Airmat, a small entrepreneurial startup company in the paper wast industry, I moved on in 1990 to something much more cutting edge an appealing. Marconi at the time was a large defence company where my role was to do 3D CAD design using Computervision CADDS 4X – back in the day it was state of the art 3D CAD software running on a mainframe computer and needed an air conditioned room and a team of three specialist computing staff just to keep it running…

Around this period the USA and Russia (Reagan and Gorbachev) had a summit meeting which turned out to be the start of the fall of Communism. It ultimately lead to large cuts in defence spending, and mass redundancies – including mine – in a period which became the deep recession of the early 1990’s, and just at the point when I’d got my first mortgage…

These tumultuous political and economic global events of that era, and my shiny new mortgage, forced me to work on a Contract basis – for which I was very unhappy about initially, but now very grateful – and 3D Cadcea Ltd was formed in 1994.

The diversity offered by 25+ years of Contract work in a host of different sectors, the use of 3D CAD tools ever since those distant days in the early 1990’s, and the constant renewal of past experiences coupled with still gaining new experience, has given me a strong understanding how to deliver efficient design productivity, and a versatility I’m very grateful for. It has also been a very engaging and satisfying working life too… Like I said earlier – the stuff of dreams!

Being a deep and holistic thinker, analytical, practical, hugely experienced, and versatile, my best output is when I’m left alone to design; particulalry ‘First of Kind’ items. It results in timely efficient drawing output complete with supporting docs comprising basic calcs, material selection reports etc.

Finally...

It bacame clear fairly early on, and is often vindicated, that ‘Do it right – once’ is the best approach to delivering fast, efficient, and accurate designs – establishing a clear design scope, doing it diligintly in one pass, with sufficient attention to detail to capture the full work extent. No more, no less. A fuller explanation is given in the ‘Least Cost Design Philosophy’ section of this website.

(What happens time and again on projects is a deadline driven approach that needs to start producing output – e.g. placing orders, getting items made, etc. This is often with an incomplete understanding of scope because it’s based on a design that’s only 60% complete – or less. The result is missed design steps, ill thought out deliverables, and subsequent re-design / design creep, and the inevitable outcome of late delivery and over budget.)

The solution is to treat design progression as output, and subject it to the usual key performance indicator (KPI) measurements used in other project phases.

For more info, go to the menu bar and select:-

Least Cost Design Philosophy

The Future...

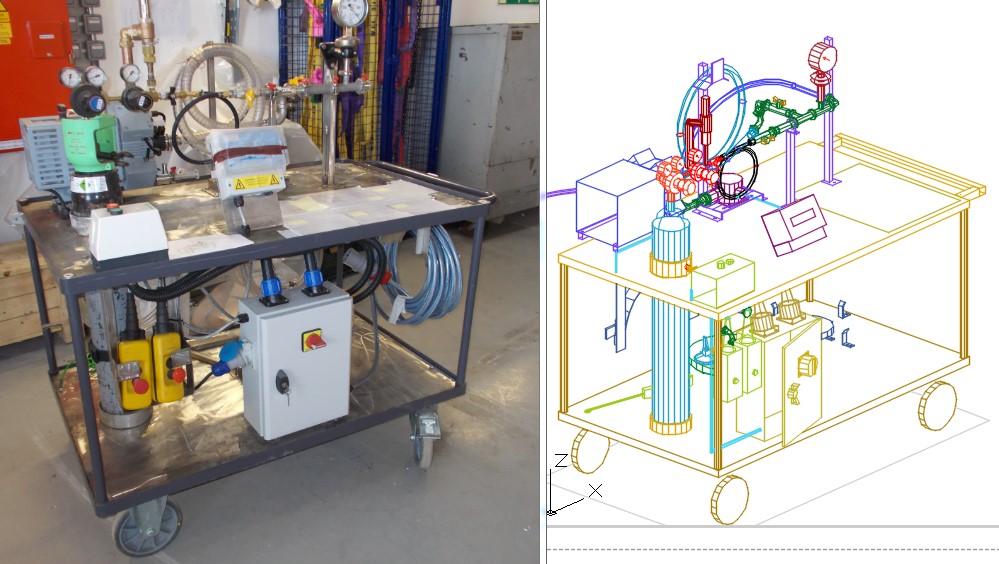

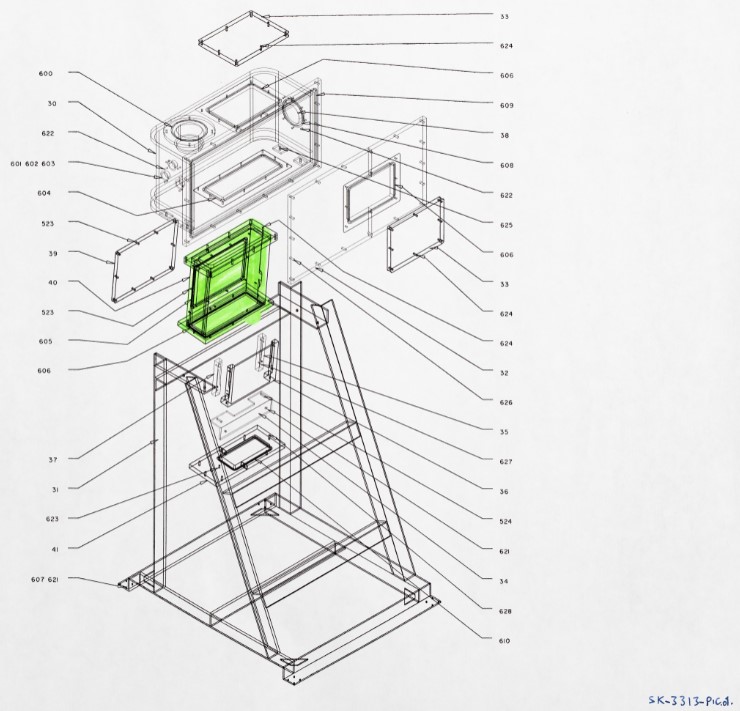

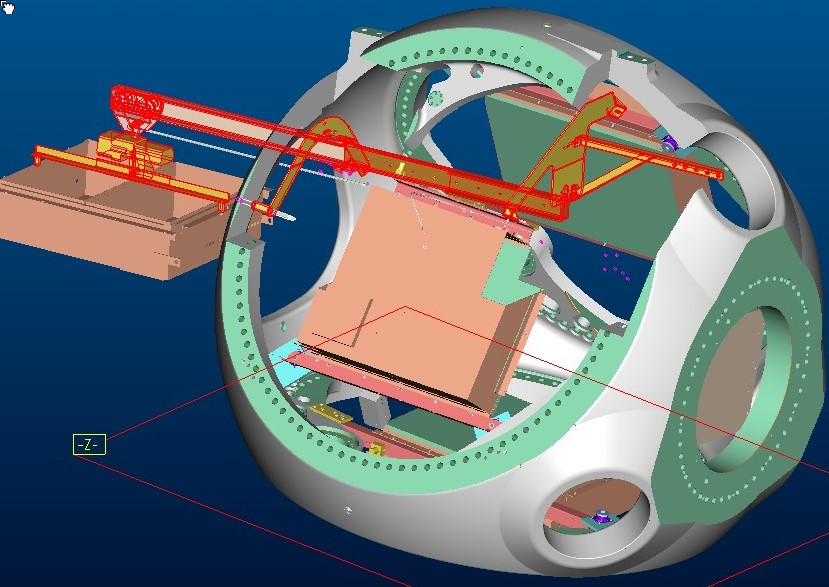

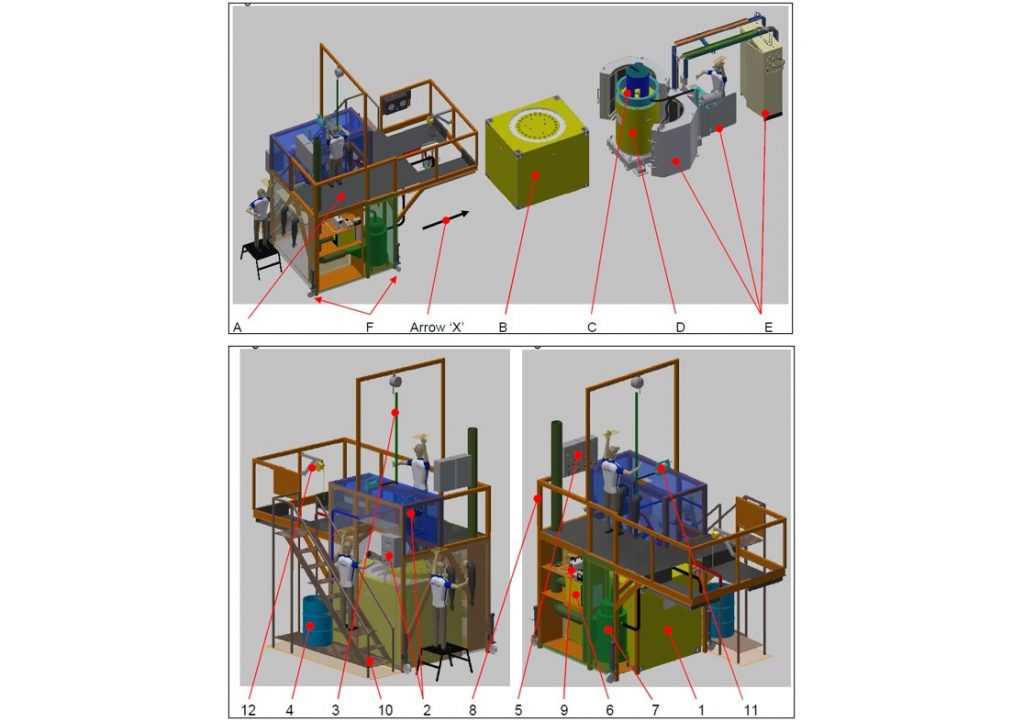

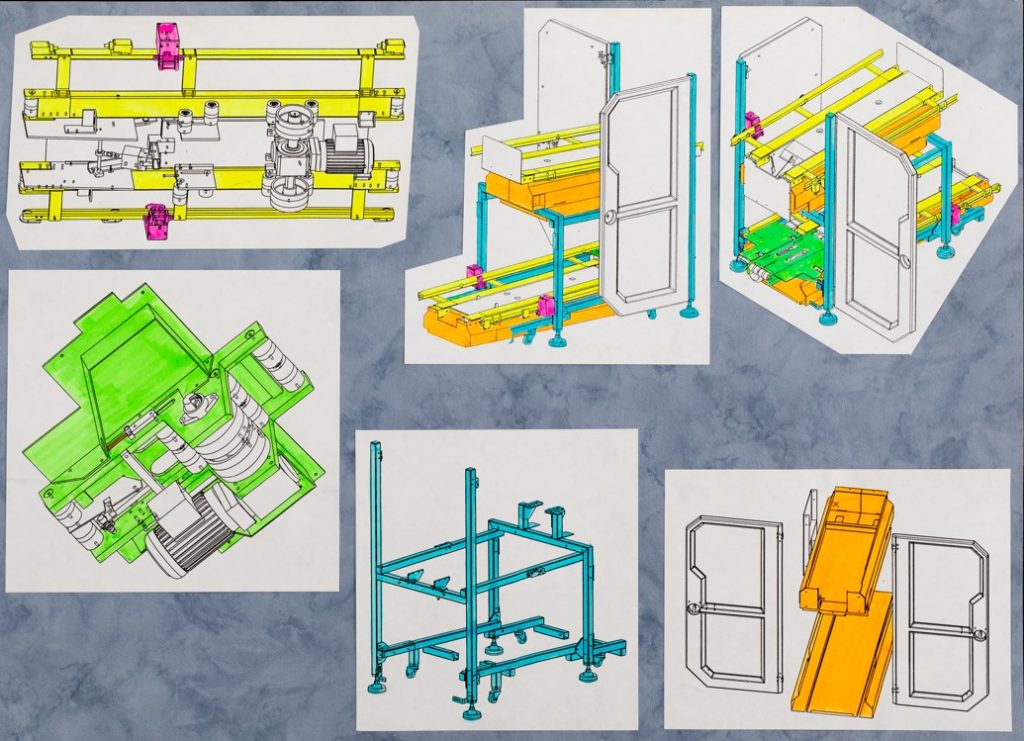

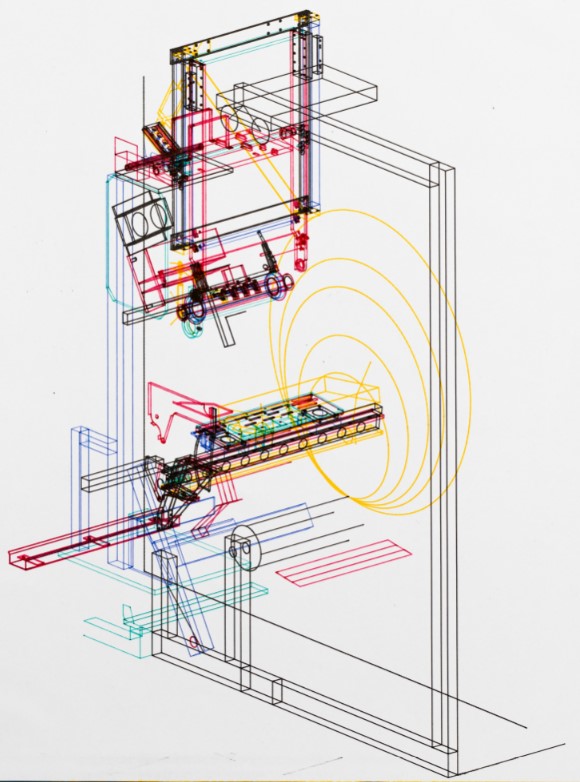

Future goals are to remain outside IR35 tax rules by working on a basis of a set number of hours, or on self contained deliverable items. Self contained deliverable items would work best, because it moves me away from being part of a large engineering team, and instead to be a satellite contributor of smaller aspects of large projects – to undertake small self contained engineering design projects that can be fully designed in up to 1000 man hours , either for small companies, or for larger organisations. In essence, taking on design briefs for stand alone ‘first of a kind’ industrial items, (such as jigs for production, fixtures for shaker tests, handling rigs, lspecialised ifting equipment, support equipment, etc.) and progressing them from concept approval, all the way through to detail design, drawing pack, and prototype build – complete with the relevant design justification documentation, calculations, substantiations, etc.

Nuclear decomissioning equipment rigs would be a key area, as would peripheral equipment items needed on large projects, or product innovation of any kind for small companies breaking into new areas of business.

Oh, and on a personal level, I still want to design and campaign my own competition car when the time comes…

I hope my journey can bring a useful and innovative engineering and design support service aimed at helping forward thinking organisations to efficiently solve thir design challenges during their own journey, and please feel free to make contact any time.

Here’s some examples of ‘First of a kind’ items designed to date:-