NEG Micon

June 2000 to July 2004.

Sector:

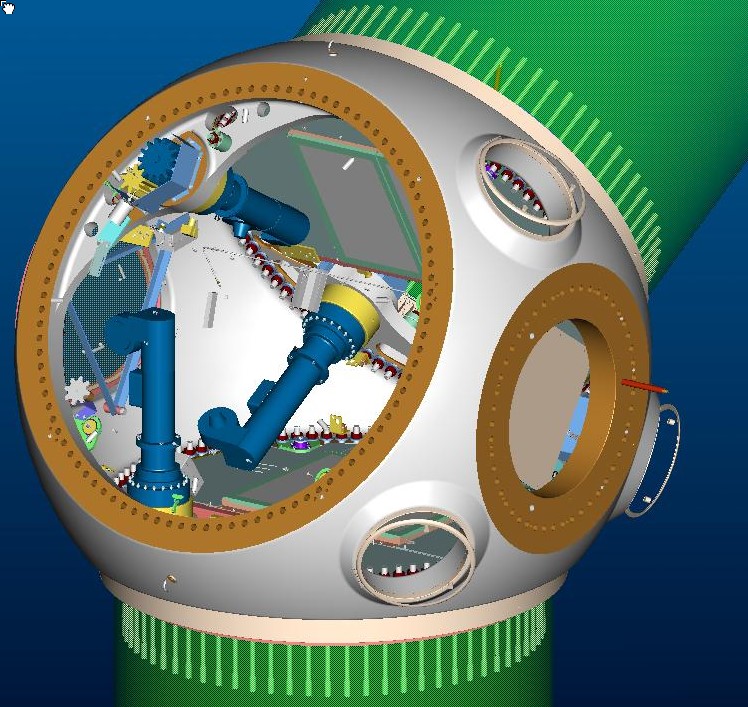

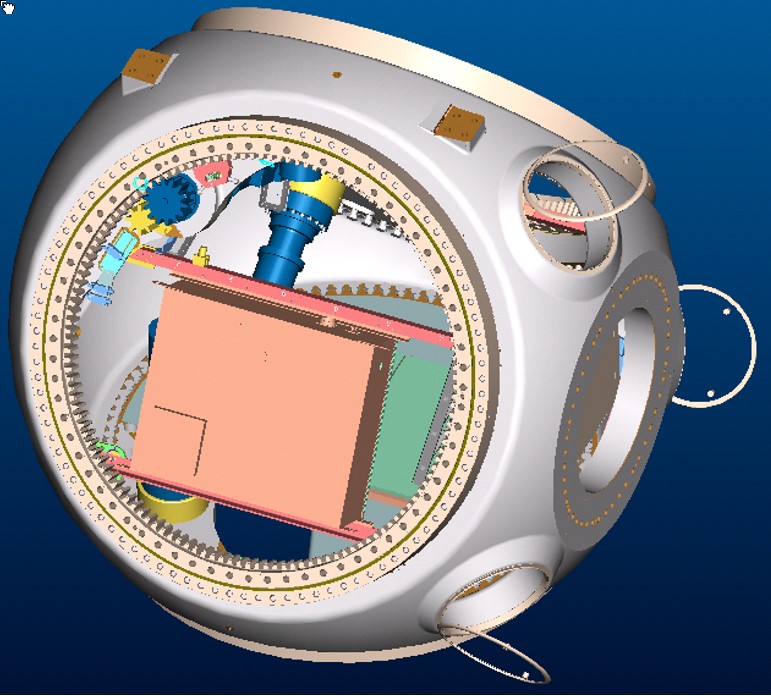

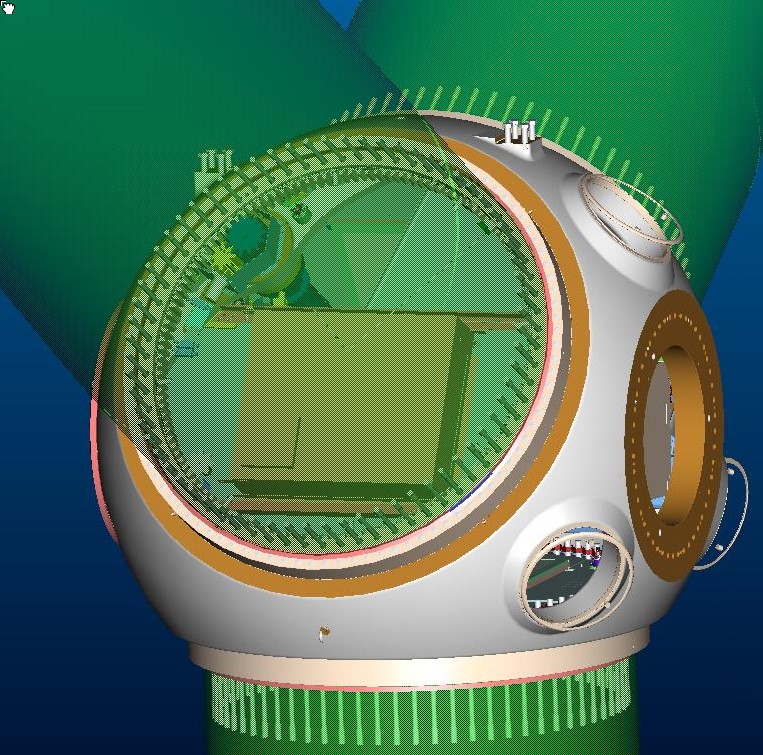

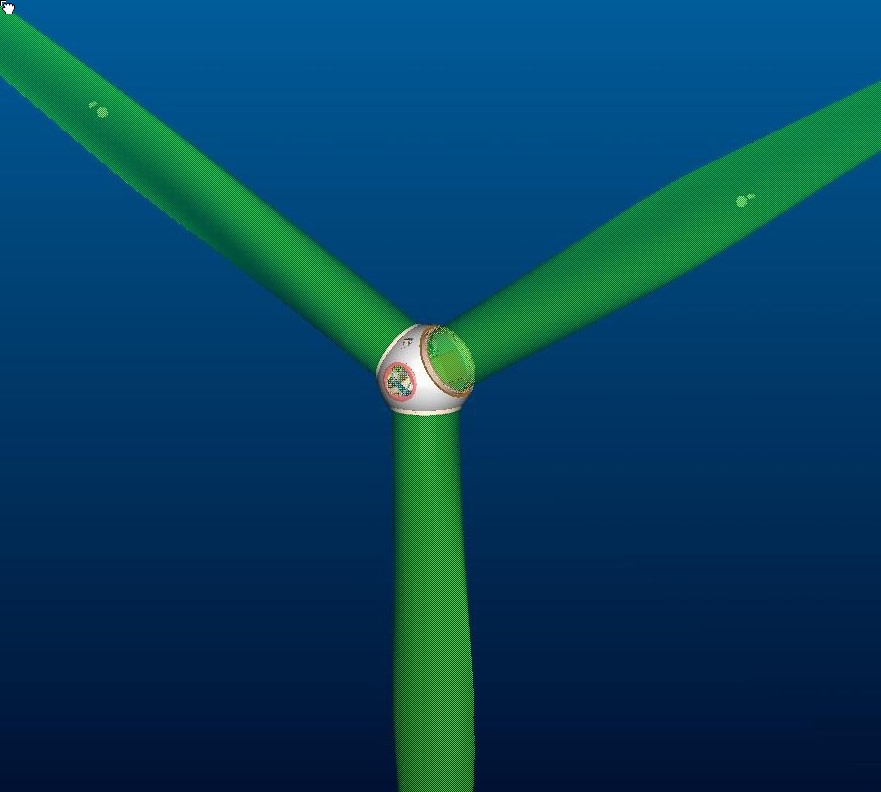

Renewable energy.(Renewables). Onshore and offshore Wind Turbine Hubs. (Electric and hydraulic pitching.)

Overview:

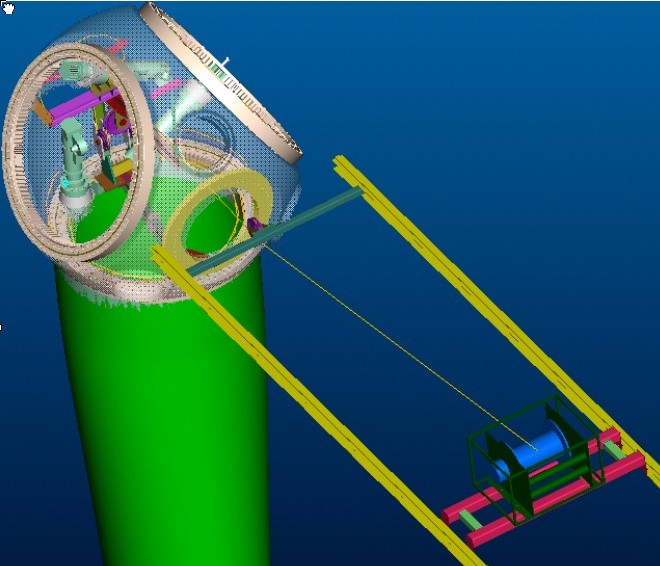

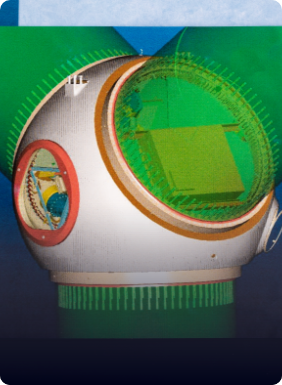

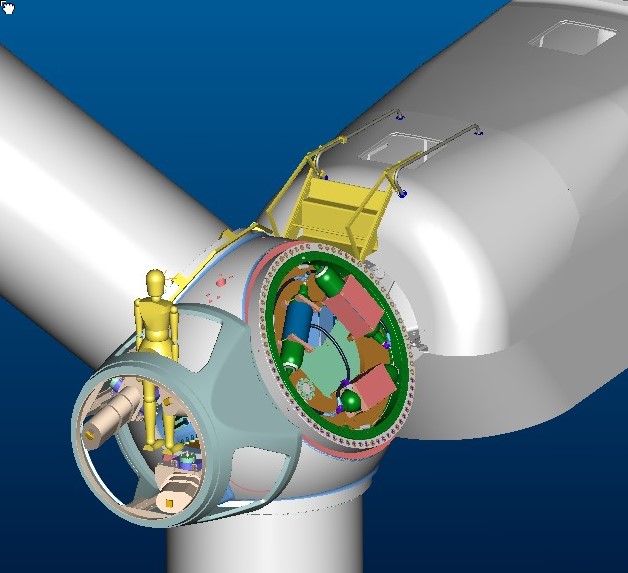

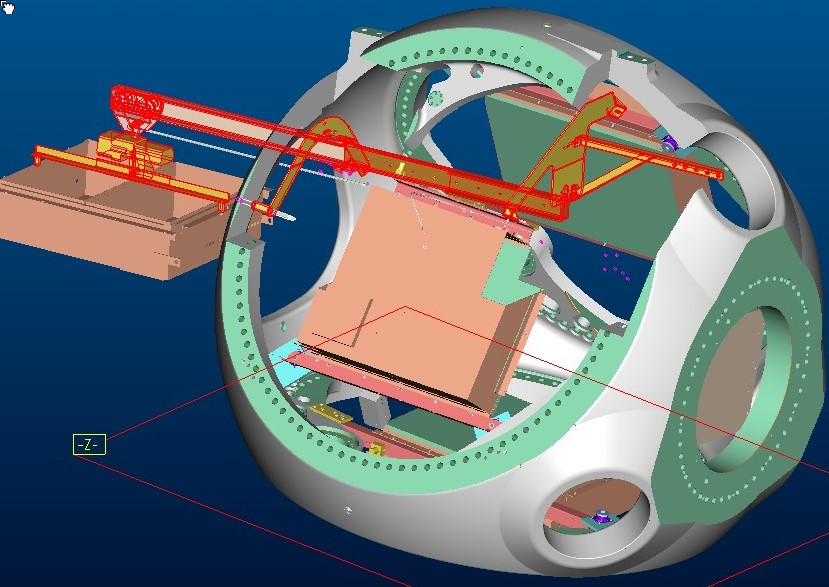

Delivered: 1/ Electrical pitching Hub internal layout designs. 2/ Bespoke handling equipment for turbine maintenance – a ‘first of a kind’ specialised portable hub crane including load calcs. 3/ Solving adverse Ergonomics for entering very large hubs and entering through front nose of hubs.

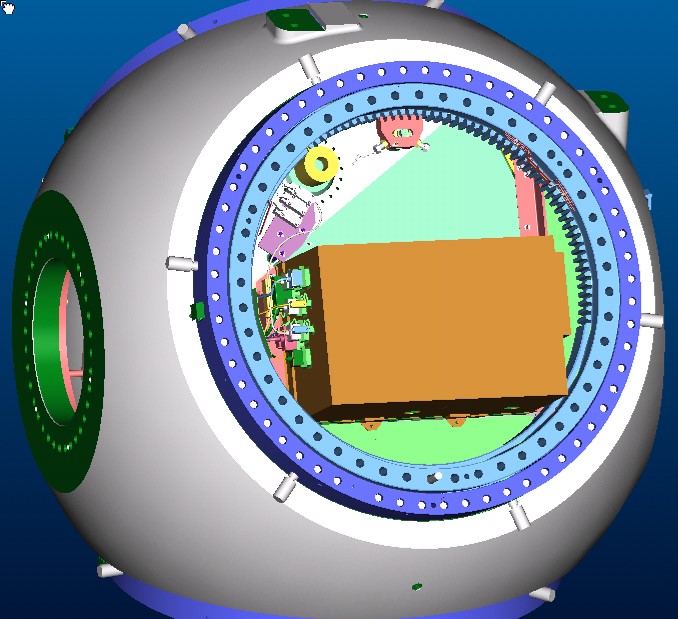

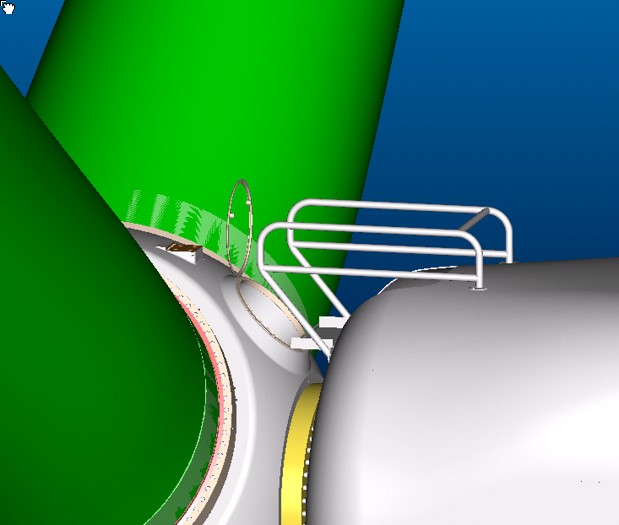

Electric pitching hub, approx 1 MW

Hydraulic pitching hub, approx. 1 MW.

Worked with:

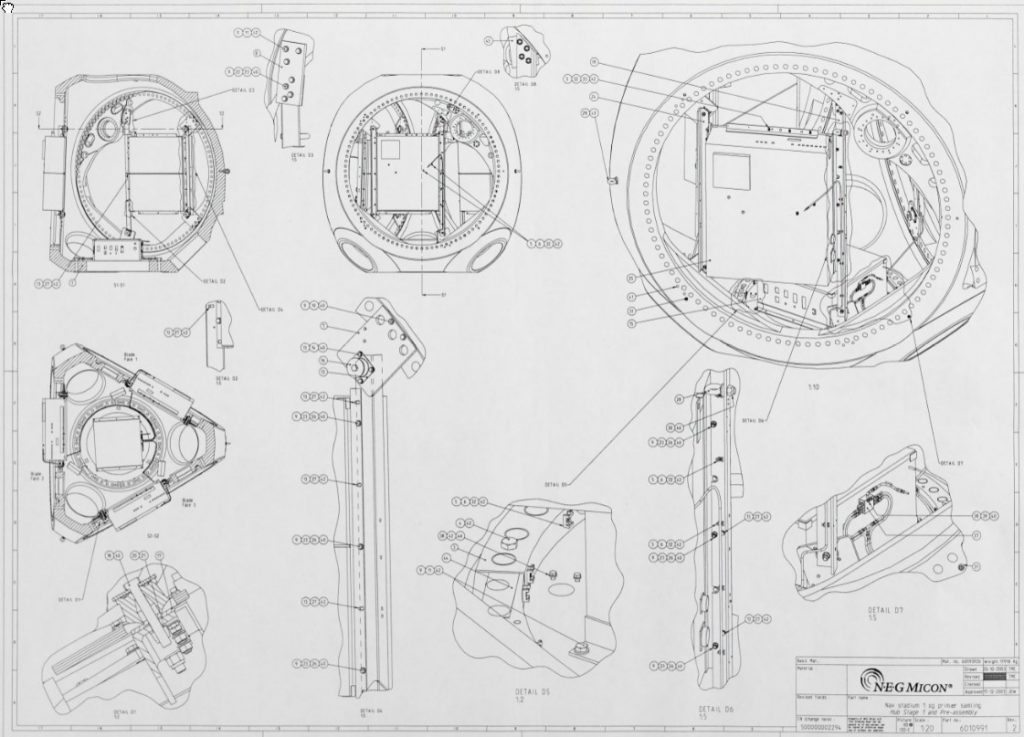

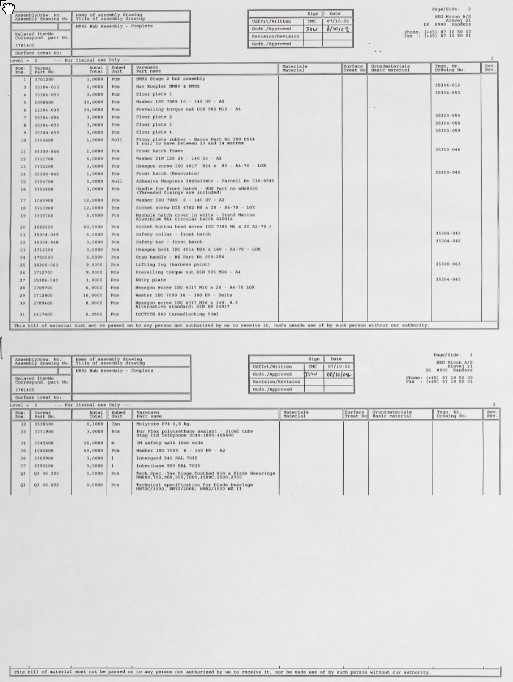

Pro-E CAD design, detail drawings, and Bills of Materials, change control + configuration.

Order placement, bid evaluation, expediting and progressing deliverables.

Authoring procedures for FAT tests / Hub ‘First Build’ instructions.

Hub castings up to 16 tonnes (3 MW) with M36 bolts for 10 tonne blades.

Anti-Vibration Mounts (AVMs) for eqpt at risk from hub flex.

Organising 3 workshop staff to do prototype builds.

Full details of this role:

- Used Pro/E 3D CAD for design & drafting of hub castings up to 16 tons (2-3 Mwatts) & associated design layout of Turbine Blade bolted joints up to M36.

- Design of mounting systems for the blade pitching & safety shut down equipment on “Active Stall” & “Pitch Regulated” turbine configurations.

- Involved mostly with Electrical blade pitching technology & partial involvement with Hydraulic blade pitching technologies.

- Attended internal design reviews regularly & responsible for workshop build team (3 people) during the build of two types of prototype hub.

- Responsible for evaluation of hub servicing & access ergonomics for turbines fitted with reduced cost spinners, or no spinner. Evaluation done by designing a wooden mock up for trials that quickly proved the viability of the proposed solution to the ergonomic challenges.

- Created Power-point slides of 3D CAD work, & authored procedures & assembly instructions for equipment such as portable hub crane FAT test doc, etc. Used SAP & Concorde MRP systems for part numbers, and parts list, drgs + change notes, and used Microsoft Excel to track orders and deliveries.

Was offered permanent employment upon purchase by Vestas.

- Innovation of specialised ‘First of a Kind’ lifting equipment & winch items for use within the turbine Hub & Nacelle. Lifting equipment used for changing 10 ton blades to negate hiring expensive offshore ‘Jack-up’ cranes. Structural design & calcs of manually portable service crane for the 250 kg motor gearboxes & controller boxes. Worked with specs for winch crane equipment, flooring, anti-vibration mounts, & Hatches.

Other images associated with this role: