Molins

Oct 1996 to Sept 1997

Sector:

FMCG factory plant. Special purpose machinery / factory machinery for cigarette mass production.

Overview:

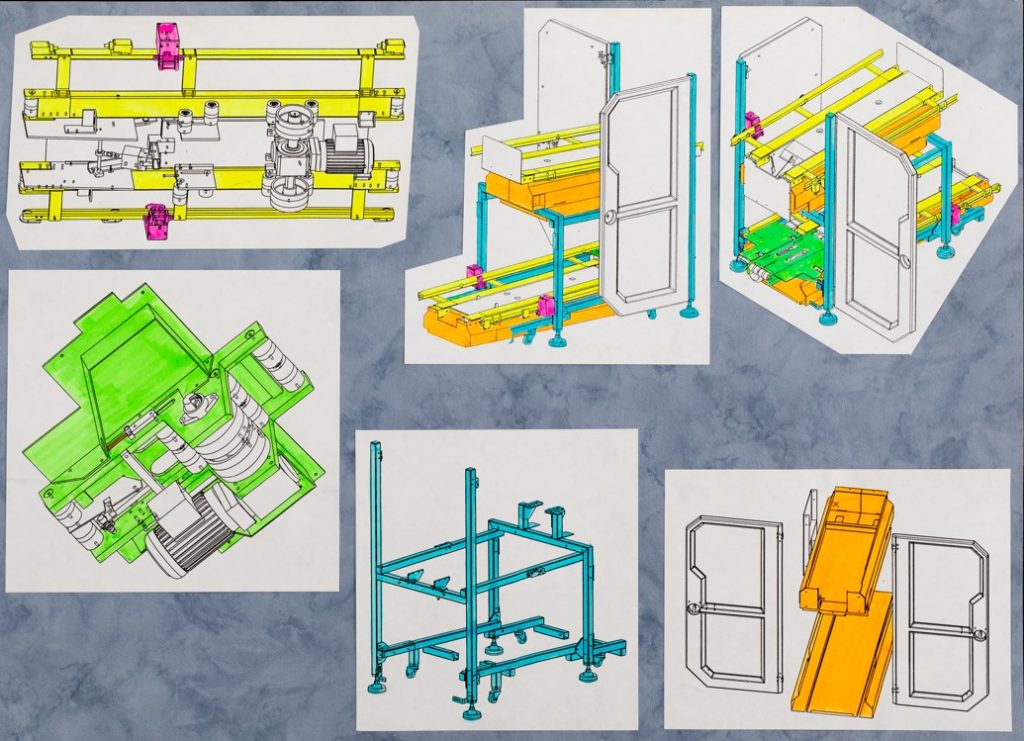

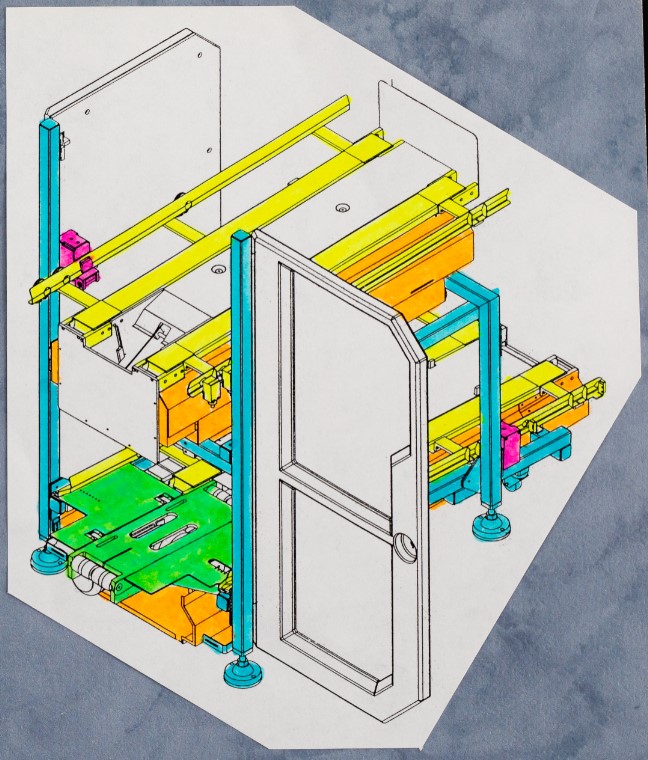

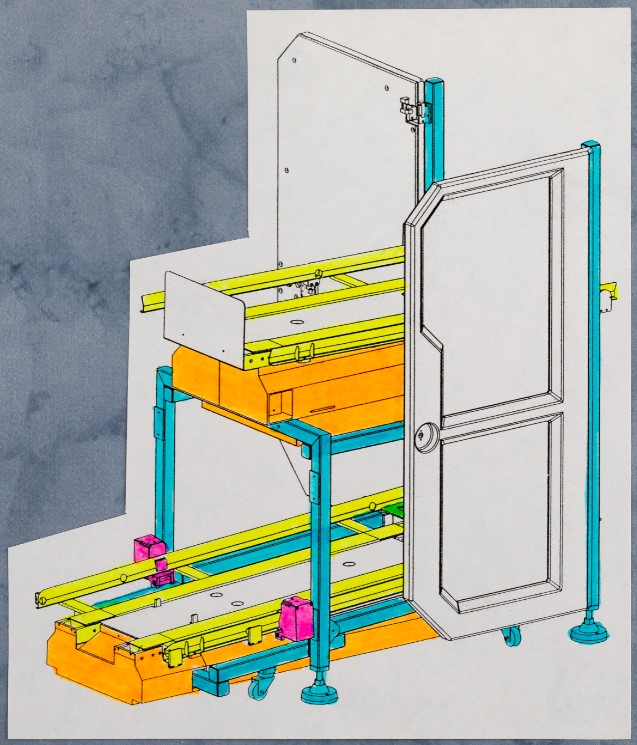

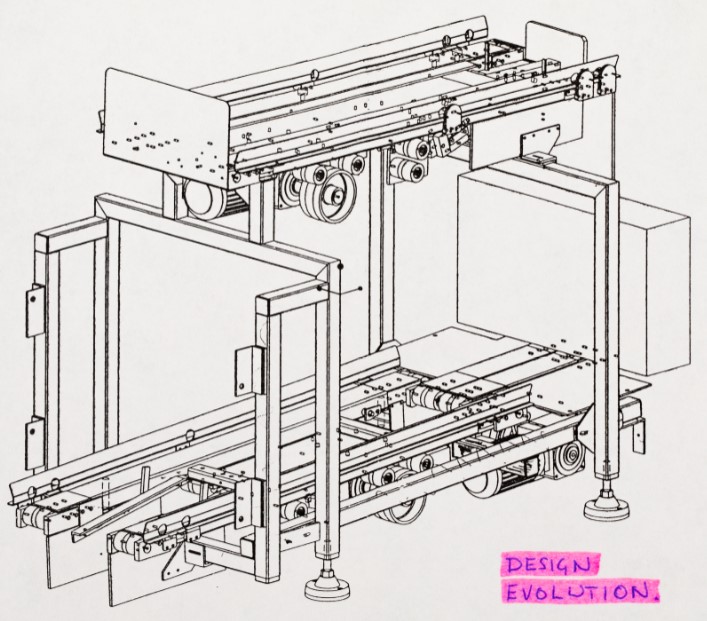

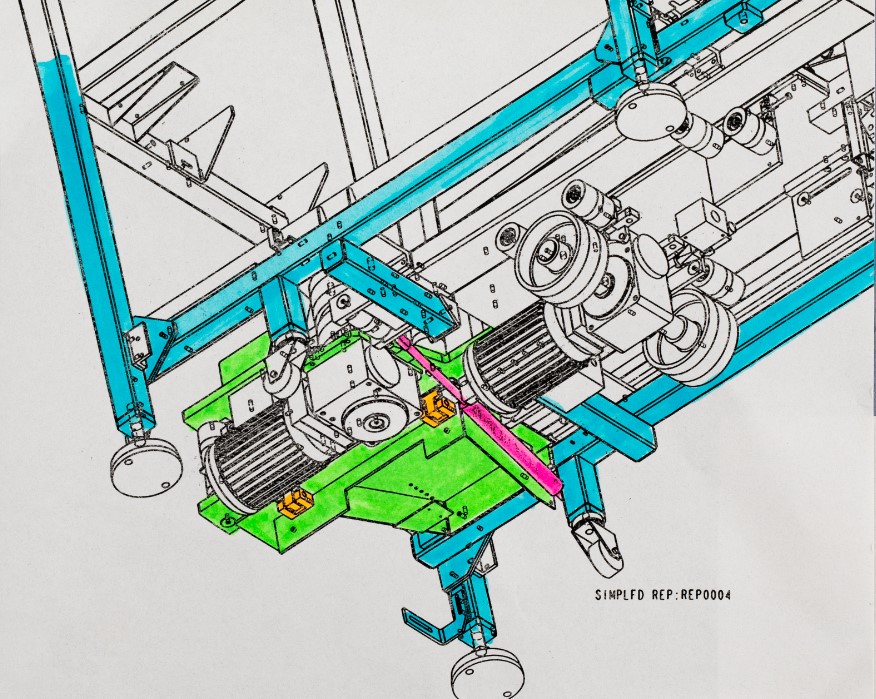

Design and draw from scratch using Pro-E 3D CAD (R17 version) a ‘first of a kind’ cigarette Buffer Stack machine for high speed (15k / min) cigarette production line machinery. Design solution innovated from a ‘Requirement Spec’ document, and the design had to interface with other major modules of factory equipment.

Work with:

1/ The design of “Full tray” out-feed section of a tray-filling machine for buffering cigarette production.

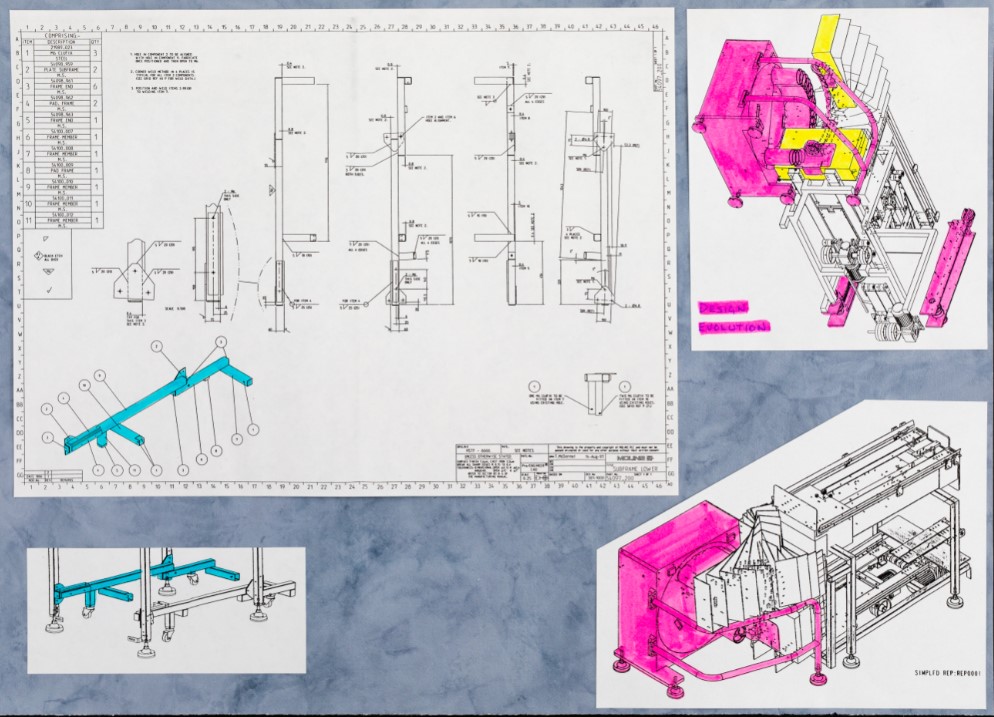

2/ Concept design of the machine, detail design, BoMs and full drawing pack, created from a requirement spec.

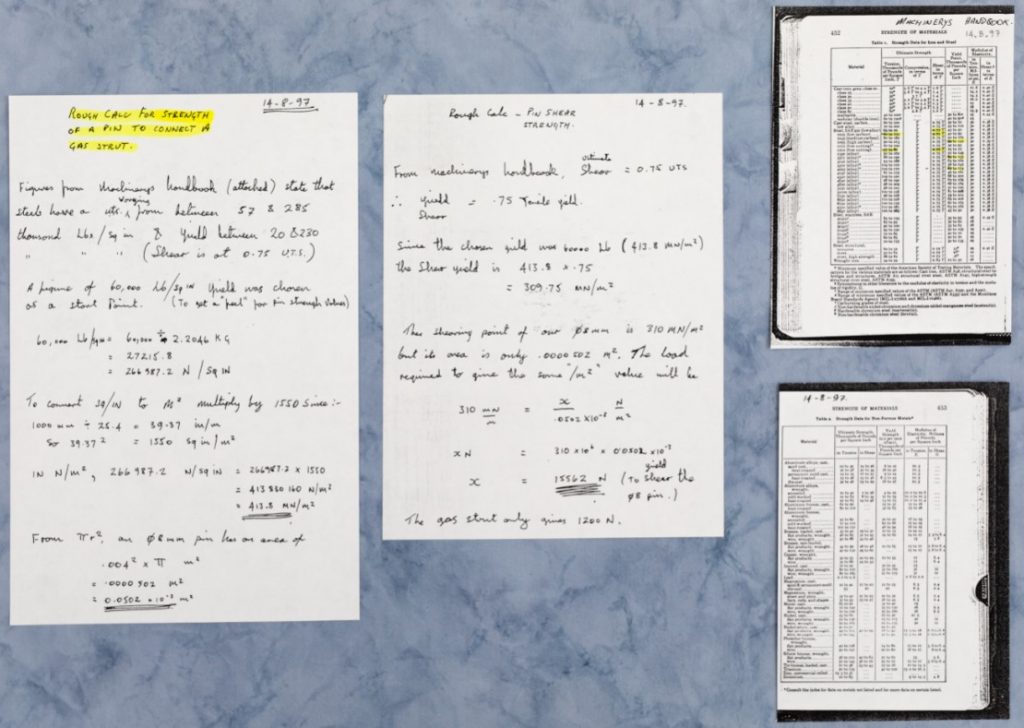

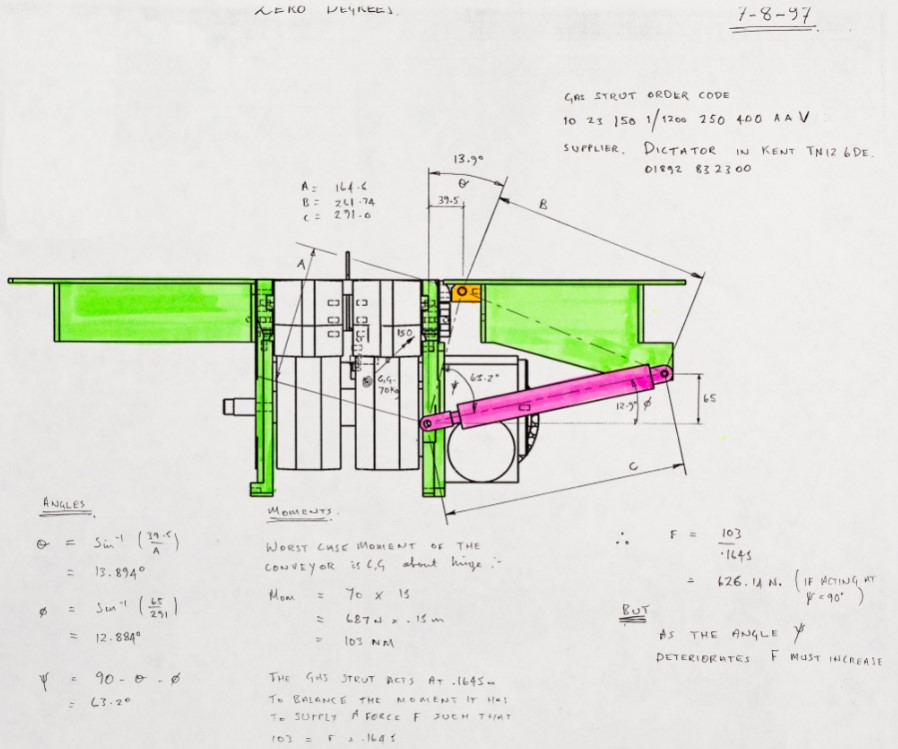

3/ Motor sizing and drive mechanisms, and calculations for moments, gas strut pin strength, and ‘topple’ accelerations.

4/ Materials and components selection, castings, guards, and welded frames.

5/ Logic control diagrams for machine functions, and

6/ Organised 3 staff for some detail drawings completion to meet deadlines, and offered permanent employment

Calculations for the Accelerator tray, and gas strut loads.

The gas strut lifts the conveyor for underside maintenance.