Applied

Nov 1994 to Aug 1996

Sector:

FMCG silicon chip processing machines for computer components (Integrated Circuits) mass production.

Sector:

FMCG silicon chip processing machines for computer components (Integrated Circuits) mass production.

Overview:

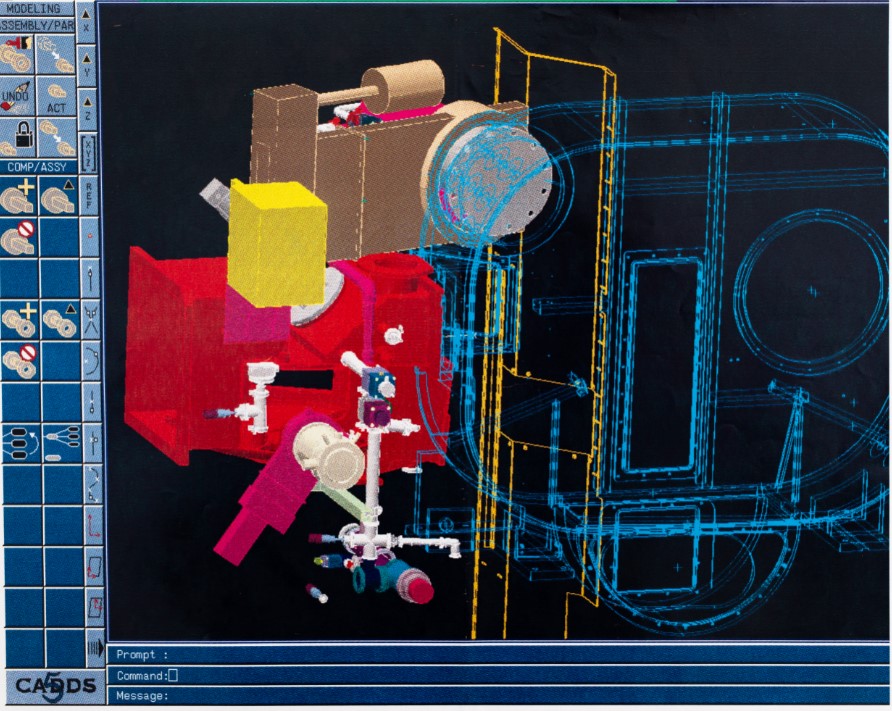

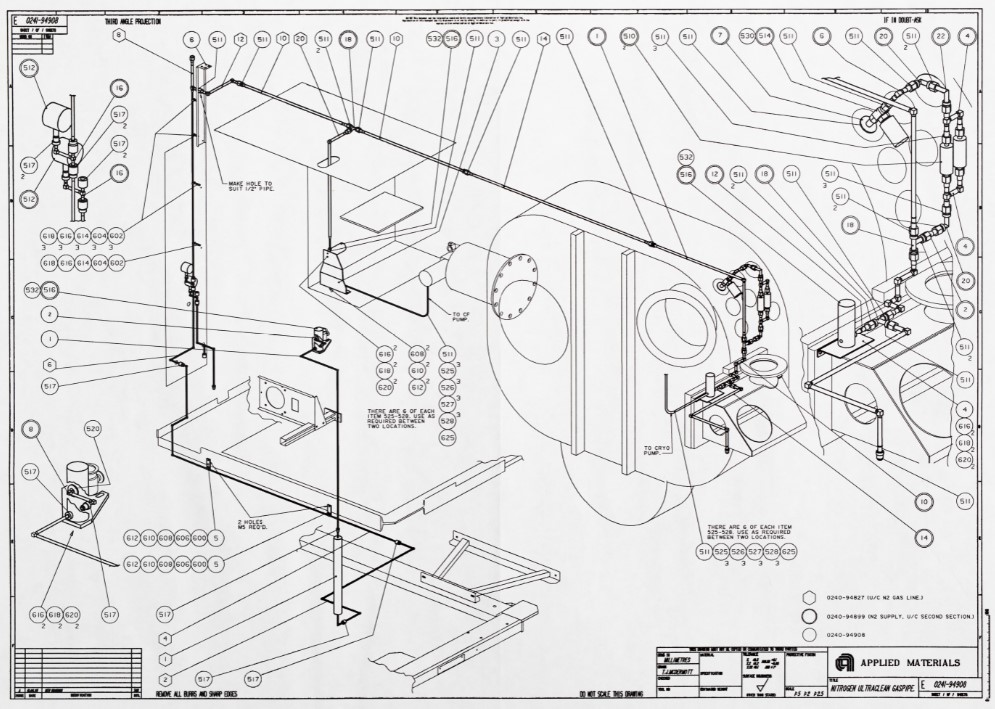

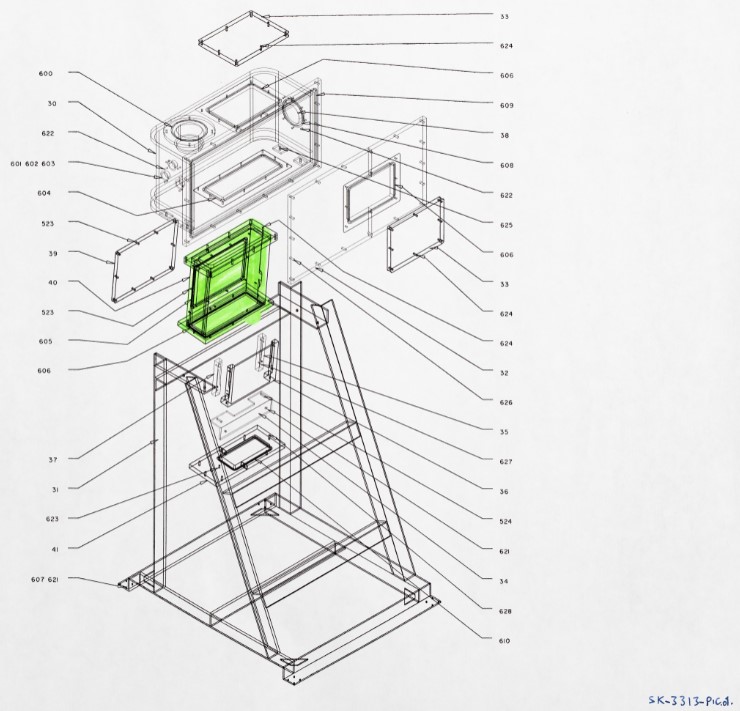

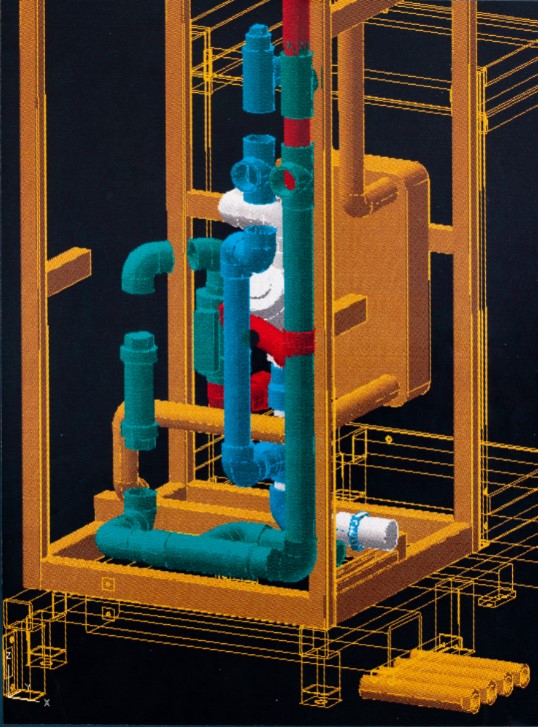

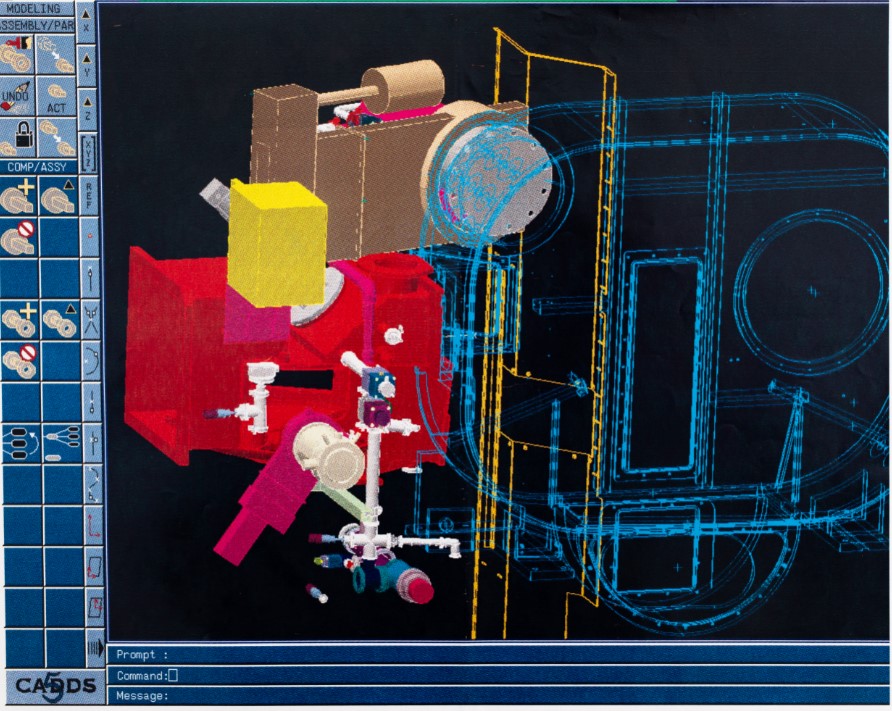

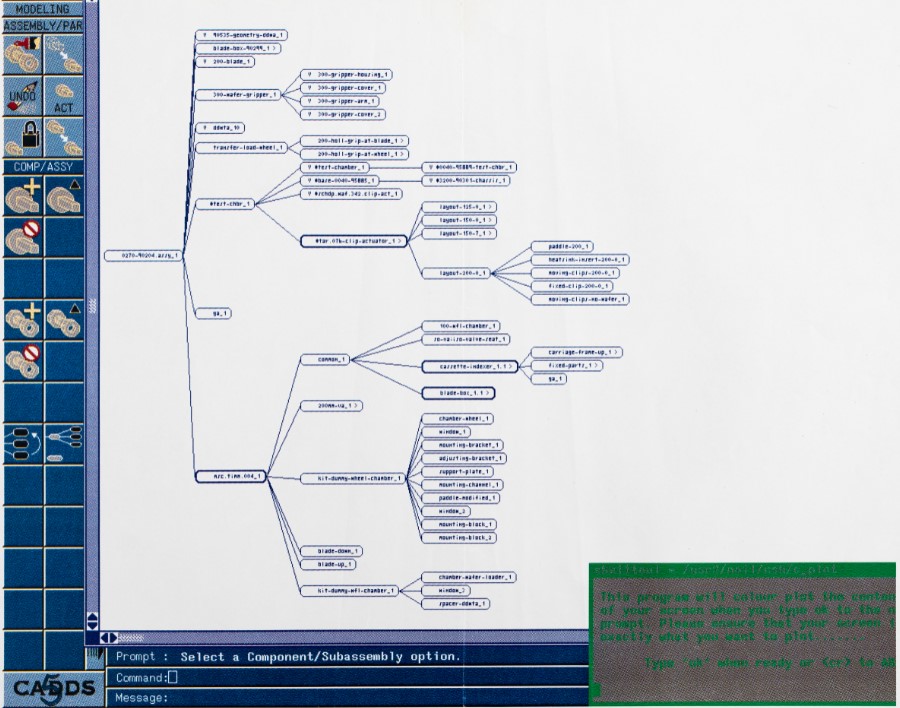

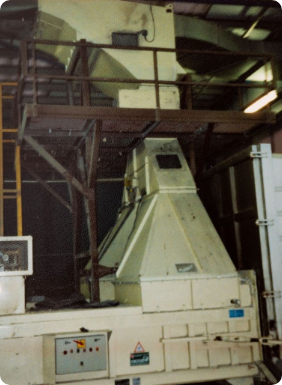

Mechanical Design – Factory Machinery. Machines incorporating a high vacuum particle physics process to manufacture semi-conductor ‘wafer’ discs – the raw material used for integrated circuits at the heart of computer processor chips.

Customer ‘special requirements’ designs in 3D on Computervision CADDS 5 for adapting the standardised machine to suit customer’s specific needs. E.g. To use stainless steel tube for gases instead of nylon tube

Worked with:

1/ Specific requirements adaptations with 3D CAD.

2/ Specialised test rig for wafer handling chamber equipment.

3/ Specialised Lifting apparatus and simple calcs.

4/ Form-Fit-Function methods for BoM configuration control / change control, and parts purchasing using ManMan stock control MRP software.

5/ 3D CAD models & detail drawings using EDM and formtek packages working in a ‘form-fit-function’ drawing environment.

6/ Offered permanent employment.