Robdale

Aug 1991 to Apr 1992

Sector:

FMCG Factory Plant / Pulp and Paper handling machinery.

Sector:

FMCG Factory Plant / Pulp and Paper handling machinery.

Overview:

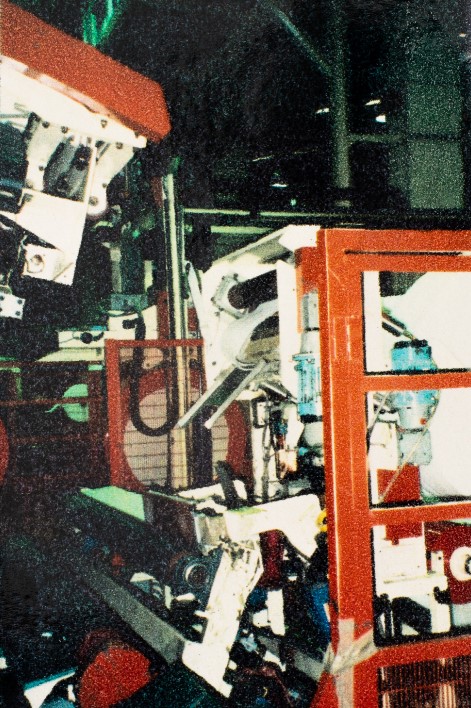

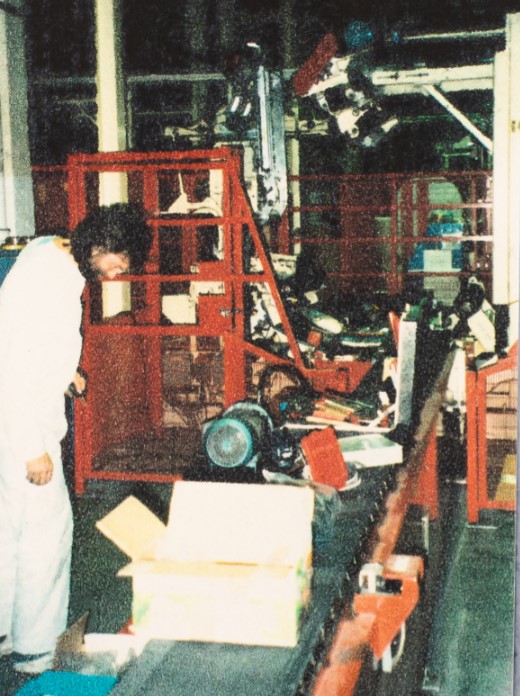

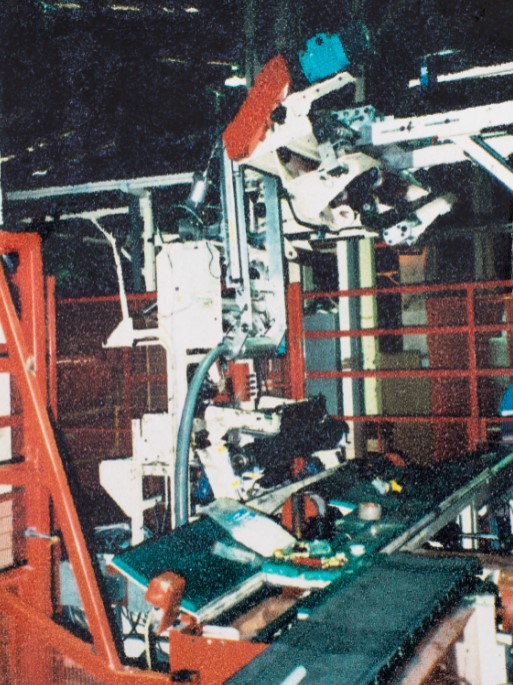

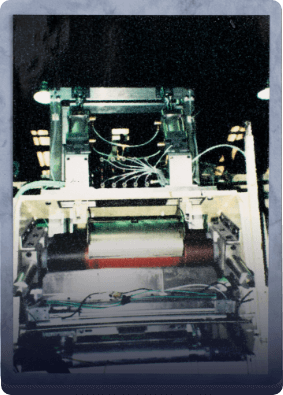

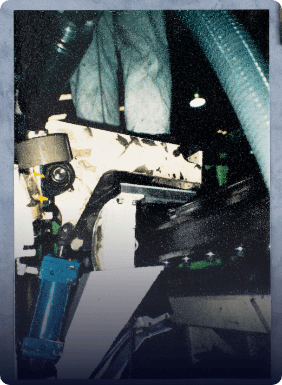

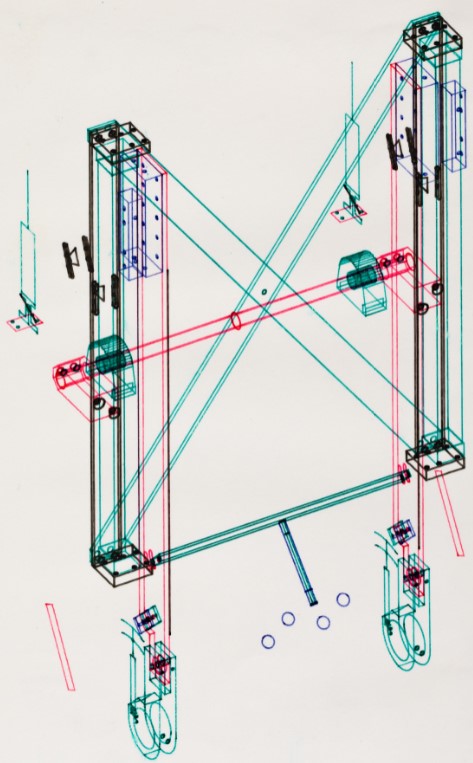

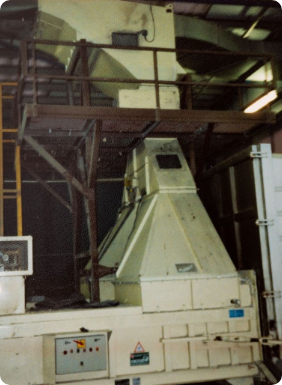

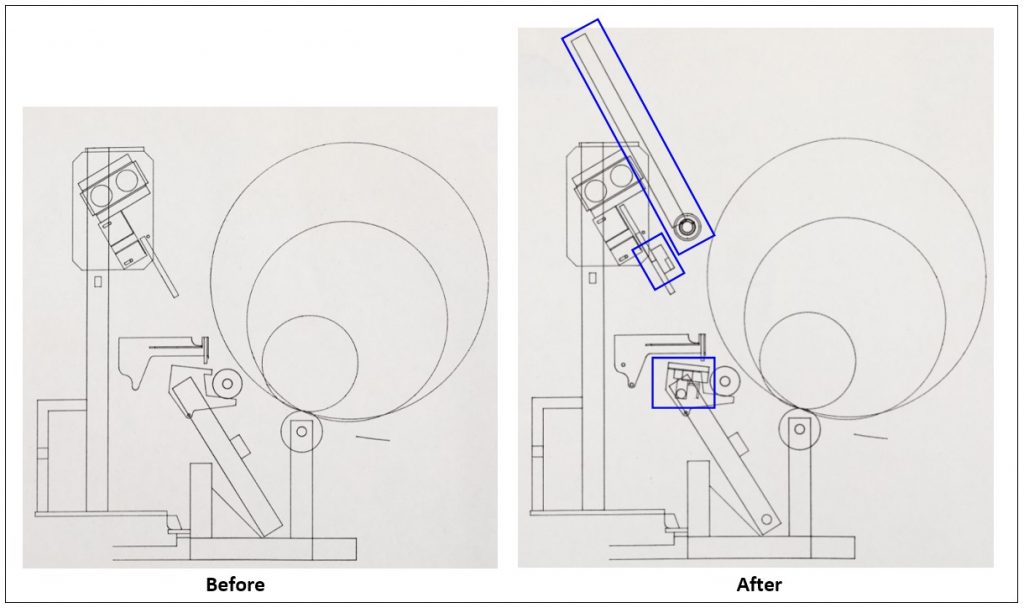

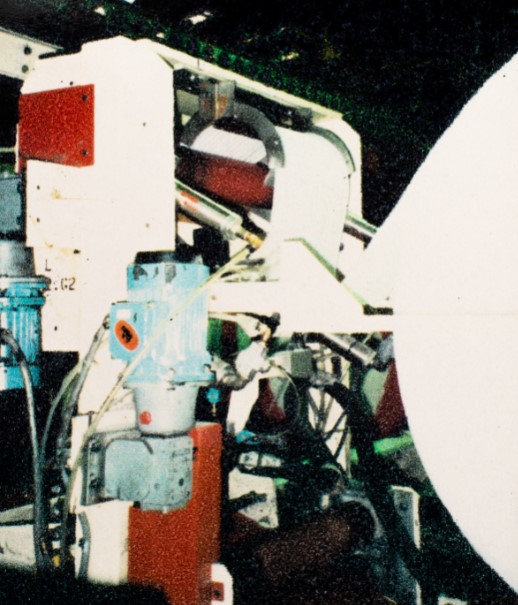

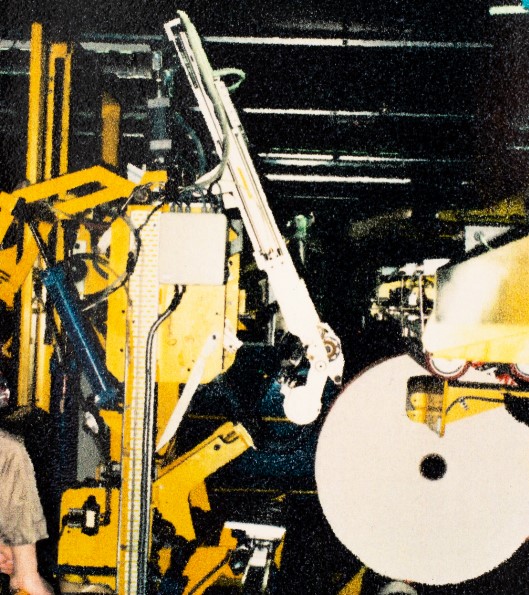

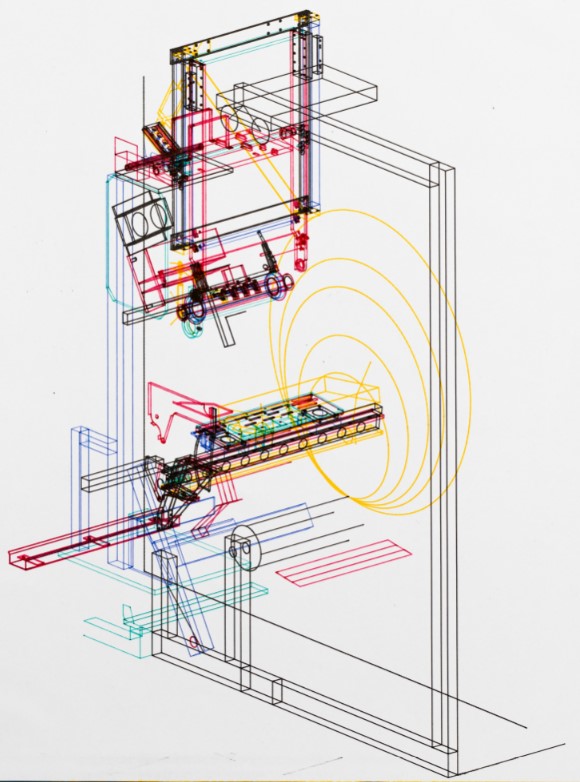

Mechanical Design of Factory Machinery modification. Update four Carbon paper reel wrapping machines to a 2 stage process in order to use an ecological wrapping material. (Single stage wrap with sheet foam no longer compliant with ecological regulations.)

Carbon copy paper reels (up to 2 tonnes each) wrapping machines got upgraded using pneumatics as the primary enabling technology for one factory site of an international paper company.

Carbon copy paper reels up to 2 tonnes each need a protective wrapping to prevent carbon copy imprints impregnating several outer layers of each roll. The foam sheet got replaced with a robust ‘crepe paper’ material.

Work with:

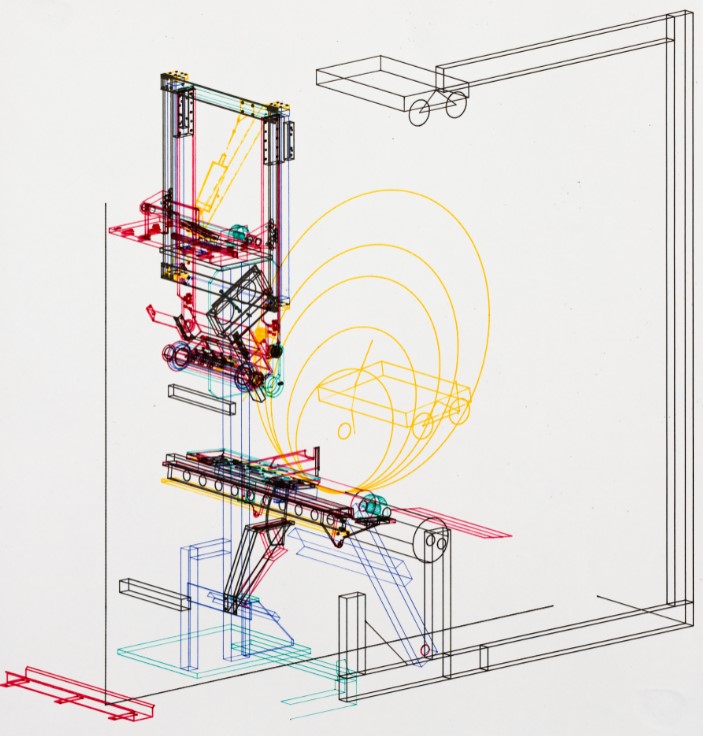

Machine survey. 3D AutoCAD design. Pneumatics specs, symbols, & mechanism design. Logic diagrams for machine control. Organised and trained a colleague in 3D CAD methods for doing the detail drawings.

Full details of this role:

A/ Mechanical Design & Project Engineer for a small special purpose machine company using AutoCAD 11 in 3D and 2D environments.

B/ Responsible for mechanical design, innovation & detailing of a wrapping machine modification, along with surveying the original machines.

C/ 3D design methods done on Autocad, and the modification was operative within 2 hours of installation.

D/ Project completed in time and budget, proving the validity of 3D CAD methods.

E/ Responsible for one member of contract staff, including giving 3D CAD training.

F/ Presented a design review alone in Belgium with the Site Director and department heads for the site, which was part of a multinational paper company.

G/ Obtained good knowledge of pneumatic equipment specifications, symbols, and designing the pneumatically driven mechanisms.

H/ Included Logic diagrams for machine control showing when machine events were due to start and end.

I/ Liaised with supplier representatives and workshop staff.

J/ Responsible for CAD hardware upgrades, organising, and configuring the CAD system for implementing 3D methods.

K/ Company went into liquidation.

Other images associated with this role are as follows: